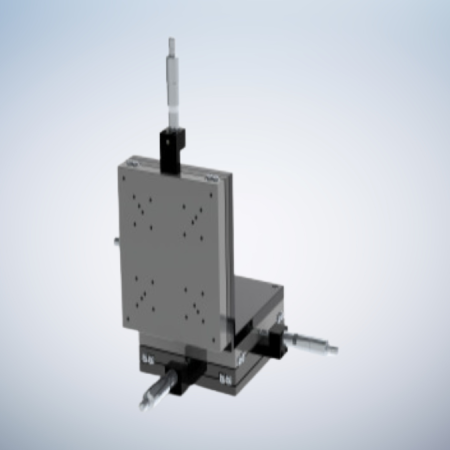

Solve the problem of retainer misalignment.

The built-in uniquely designed rack & gear mechanism completely solves the problem of retainer misalignment. It can be safely used for applications such as vertical shafts where Crossed Roller Guides have been difficult to use in the past. Even if the operating speed is increased, there is no need to worry about cage misalignment, so even if the machine is operated for a long time, there is no need to correct cage misalignment.

Installation dimensions are completely interchangeable!

It adopts an original structure with racks installed inside the track table, and its installation dimensions are completely interchangeable with conventional crossed roller linear guides. The overall dimensions are the same, which is not only suitable for new uses, but also can easily replace the original crossed roller linear guide on mechanical equipment without changing the installation dimensions. Smooth movement with extremely high precision. This is a non-loop type linear guide equipment. The high-precision track surface and ultra-precision rollers with strictly controlled length dimensions are arranged at right angles, allowing smooth movement with extremely high precision. It solves the tiny running runout inherent in loop-type linear guide equipment and achieves extremely high feeding accuracy. Since frictional resistance is extremely small and linear motion without stick-slip can be achieved, the tracking performance of small feed instructions is excellent, and positioning accuracy is expected to be further improved.

Reviews

There are no reviews yet.