POWER SPRINGS/Spiral Torsion Springs

Product SKU: POWER SPRINGS/Spiral Torsion

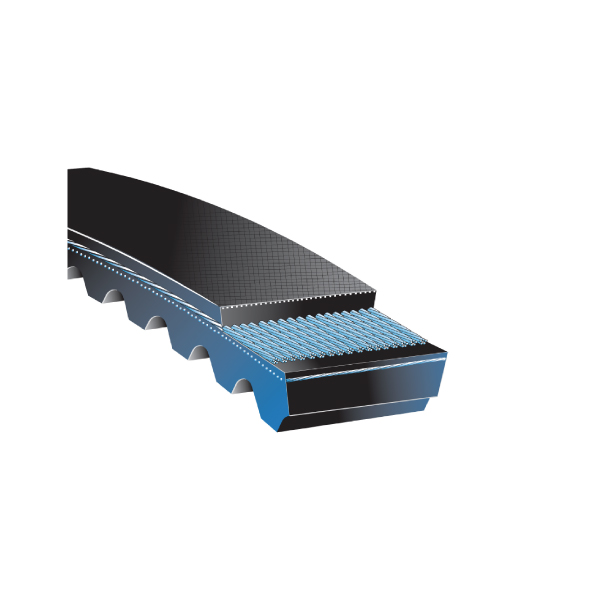

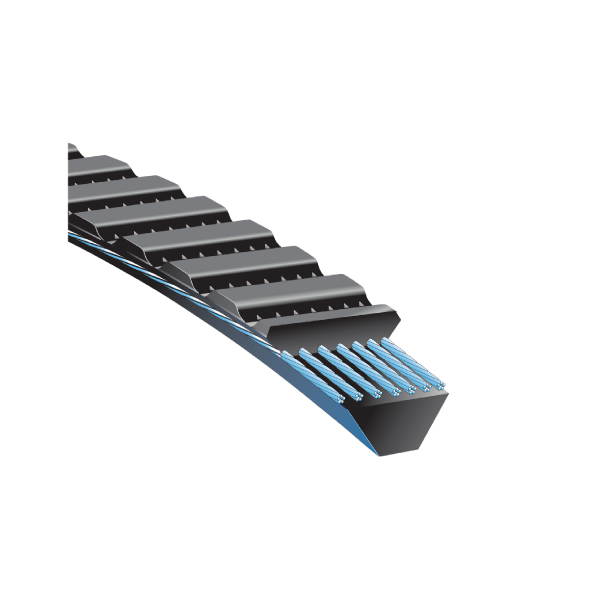

Availability: In StockTSMC Spiral Torsion Springs is also known as clock springs, flat spiral spring or spiral torsion springs. They are typically manufactured from high carbon steel or stainless steel that wound in the balanced state and are characterized by their coils' condition not contacting during operation. The inner end of these springs is fixed. The other end attached to the different components that are rotating the spring torque. This design offers reduced force, also reduce friction to zero (coil friction-free) when installed correctly.

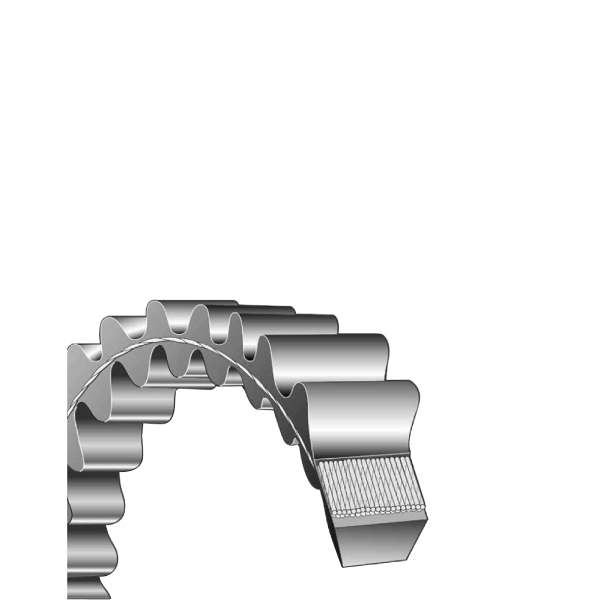

Spiral Torsion Springs are the most commonly used type of flat spring and are sometimes used in place of the traditional torsion spring as they rotate in circular movements. The torque deliver per revolution is linear for the first 360 degrees, at more significant angular rotation, the coils begin to close on the arbour. The torque per turn increases rapidly also per revolution on nonlinear when closer to the axis. Thus these type of springs is ideally suited for applications requiring less than 360° of angular rotation.

When considering a Power Spring design, there are four critical factors, such as Bore/ shaft (ID/OD), Load, Working height at which the load is applied. Material desired and the other input parameters containing the wire thickness, wire radial wall, active number of turns, work height, and load at work height. The input data, as shown on the left table. And calculation results with spring rate (stiffness), working load (±10%), outer diameter at solid height, Working curve and Life cycles prediction where found in the down table.